Danfoss H1P69 Closed-Circuit Piston Pumps

Danfoss H1P closed circuit axial piston pumps are high-performance hydraulic pumps designed for use in a variety of industrial and mobile applications. These pumps are characterized by their closed circuit design, which allows them to circulate hydraulic fluid within a system without the need for an external tank. They are equipped with axial pistons, which move in a linear motion along the axis of the pump, providing a smooth and efficient flow of fluid. The H1P pumps have a wide range of control options, including pressure and flow control, as well as a variety of mounting options to suit different application requirements. They are suitable for use with a variety of fluids, including mineral oils, synthetic oils, and water-glycol mixtures. Overall, the Danfoss H1P closed circuit axial piston pumps offer a reliable and efficient solution for a wide range of hydraulic systems.

Feature

Danfoss H1P closed circuit axial piston pumps have a number of characteristics that make them well-suited for various applications.

- Perfect fit: The H1P pumps are available in a wide range of displacements, making it easy to find the perfect fit for your specific application.

- Efficiency: These pumps are designed with an optimized profile and design, which helps to improve their overall efficiency.

- Compactness: The H1P pumps have a compact design, making them easy to install in tight spaces.

- Clean side and flexibility: The clean side design of these pumps allows for easy maintenance and reduced contamination, while the flexible mounting options make it easy to install them in a variety of configurations.

- Precise control and reliability: The H1P pumps have a variety of control options, including pressure and flow control, which allows for precise control and reliable operation.

- Wide range of displacements: As mentioned, these pumps are available in a wide range of displacements, making it easy to find the perfect fit for your application.

- High pressure capability: The H1P pumps are capable of operating at high pressures, making them suitable for use in a variety of demanding applications.

- Variety of control options: Automotive Control (AC), Electrical Displacement Control (EDC), Fan Drive Control (FDC), Forward-Neutral-Reserve Control (FNR), Mechanical Displacement Control (MDC), Non-Feedback Proportional Electric Control (NFPE).

- Optimized profile and design: The integrated Gerotor charge pump design including pressure balanced port plates reduces volumetric losses to a possible minimum.

Danfoss H1P Closed Circuit Axial Piston Pumps For Sale

We offer the Danfoss H1P Closed Circuit Axial Piston Pumps at a very high cost-performance ratio, as there are various models of the Danfoss H1P Closed Circuit Axial Piston Pumps with varying prices. To obtain a specific price quote, please contact our account manager.

Price Range:$1800-$2500

Specifications

| Feature | 45 | 53 | 60 | 68 | 69 | 78 | 89 | 100 | 115 | 130 | 147 | 165 | 210 | 250 | 280 |

| Displacement cm 3[in3] | 45.0[2.75] | 53.8[3.28] | 60.4[3.69] | 68.0[4.15] | 69.2[4.22] | 78.1[4.77] | 89.2[5.44] | 101.7[6.21] | [7.03] | [7.93] | [8.98] | 165.1[10.08] | 211.5[12.91] | 251.7[15.36] | 280.2[17] |

| Rated speed, min-1(rpm) | 3400 | 3400 | 3500 | 3500 | 3500 | 3500 | 3300 | 3300 | 3200 | 3200 | 3000 | 3000 | 2600 | 2600 | 2600 |

| Max.speed, min 1(rpm) | 3500 | 3500 | 4000 | 4000 | 4000 | 4000 | 3800 | 3800 | 3400 | 3400 | 3100 | 3100 | 2800 | 2800 | 2800 |

| Max.working pressure, bar[psi] 1) |

420 [6092] |

380 [5511] |

420 [6092] |

380 [5511] |

450 [6527] |

450 [6527] |

450 [6527] |

450 [6527] |

450 [6527] |

450 [6527] |

450 [6527] |

450 [6527] |

450 [6527] |

450 [6527] |

420 [6092] |

| Max pressure, bar [psi] |

450 [6527] |

400 [5802] |

450 [6527] |

400 [5802] |

480 [6962] |

480 [6962] |

480 [6962] |

480 [6962] |

480 [6962] |

480 [6962] |

480 [6962] |

480 [6962] |

480 [6962] |

480 [6962] |

450 [6527] |

| Weight dry, kg[lb] (without P TO/filter) |

single:41[90]tandem : 65[143] | single: 50 [110] tandem: 96.2[212] | 56 [123] |

56 [123] |

62 [137] |

62 [137] |

83 [187] |

83 [187] |

96 [211] |

96 [211] |

163 [360] |

163 [360] |

163 [360] |

||

| Mounting flange | SAEB, 2-bolt | SAE C,4-bolt | SAED, 4-bolt | SAE E, 4-bolt | |||||||||||

Markets and Applications

The Danfoss H1P closed circuit axial piston pumps are suitable for use in a variety of markets and applications. Some examples of these markets and applications include:

- Agriculture: These pumps can be used in a variety of agriculture-related applications, such as irrigation systems, sprayers, and combine harvesters.

- Construction: The H1P pumps can be used in construction equipment, such as excavators, bulldozers, and concrete mixers.

- Crane and material handling: These pumps can be used in cranes and other material handling equipment to provide the hydraulic power needed to lift and move heavy loads.

- Forestry: The H1P pumps can be used in forestry equipment, such as logging trucks and log loaders.

- Heavy machinery: These pumps are suitable for use in a variety of heavy machinery, including loaders, bulldozers, and graders.

- Lawn and turf: The H1P pumps can be used in lawn and turf care equipment, such as mowers and turf rollers.

- Offshore oil and gas applications: These pumps are suitable for use in offshore oil and gas drilling and production operations.

- Onshore oil and gas applications: The H1P pumps can be used in onshore oil and gas operations, such as pipeline construction and maintenance.

- Road building: These pumps can be used in road building equipment, such as asphalt pavers and road rollers.

- Thrusters: The H1P pumps can be used in thrusters to provide the hydraulic power needed to move and position ships and other marine vessels.

- Wheel loaders: These pumps can be used in wheel loaders to provide the hydraulic power needed to lift and move heavy loads.

- Winches: The H1P pumps can be used in winches to provide the hydraulic power needed to lift and move heavy loads.

Dimensions

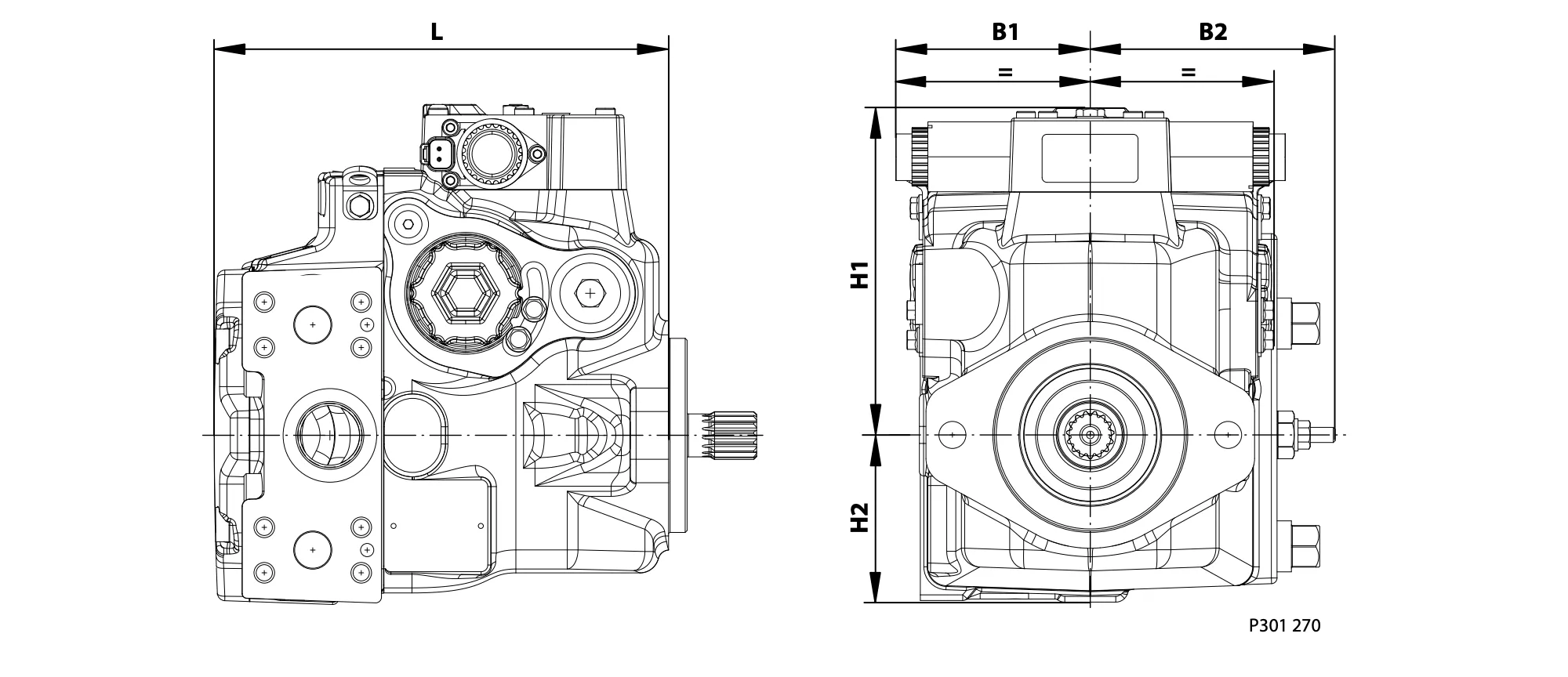

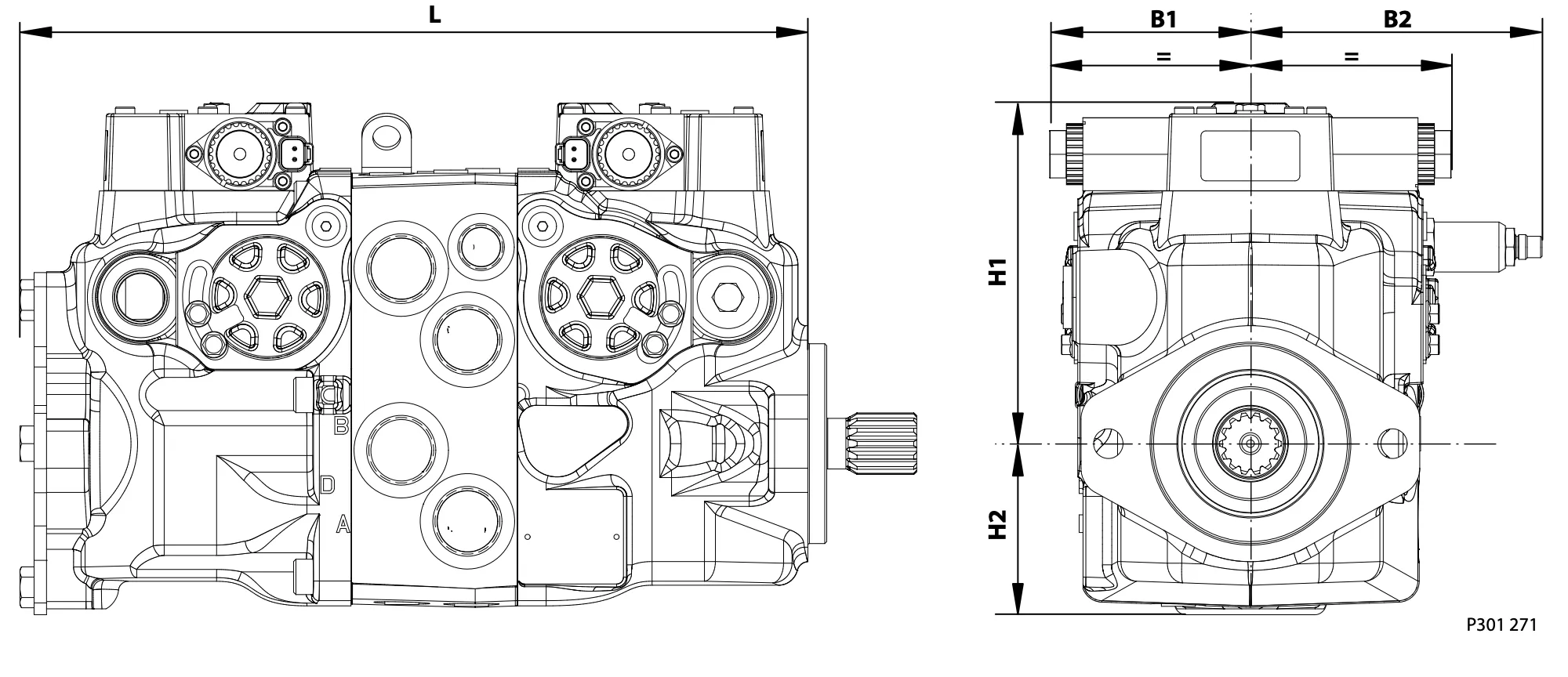

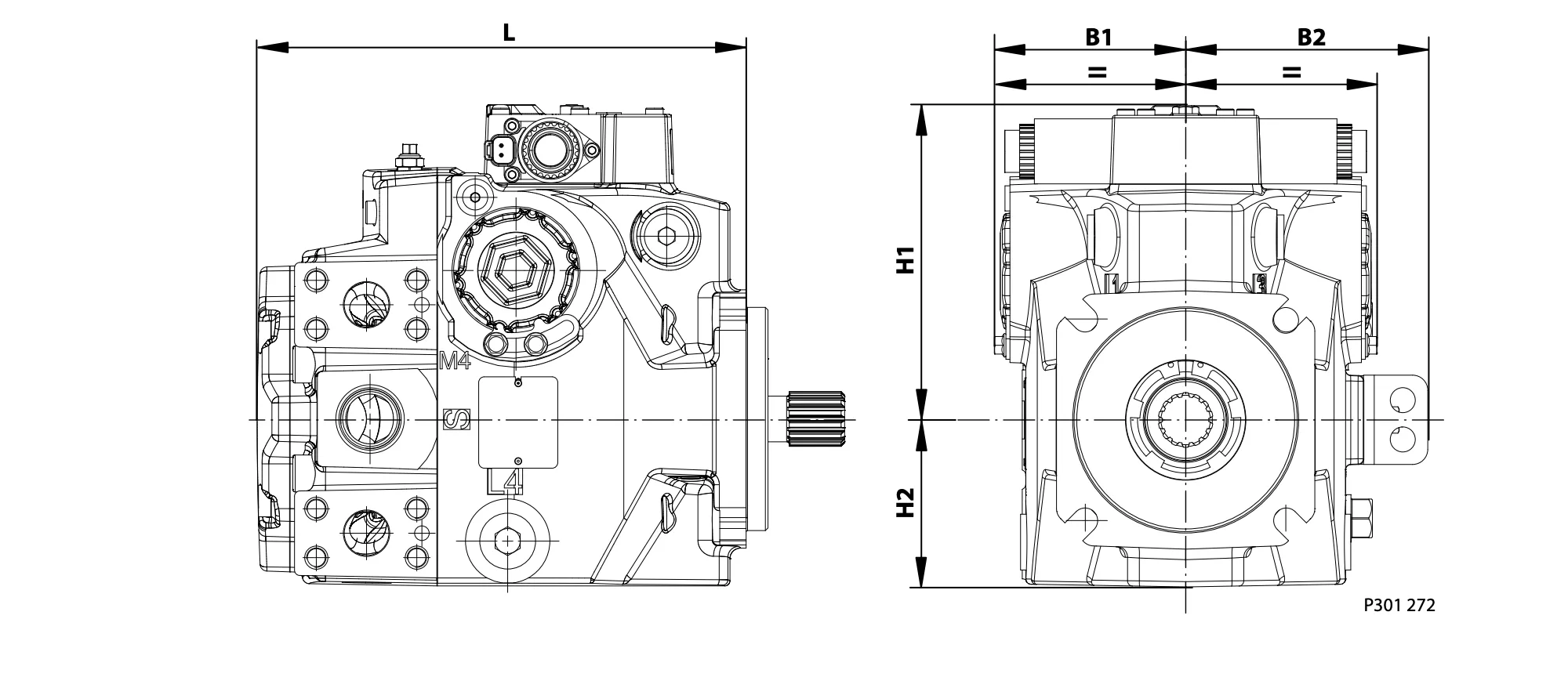

| Frame size 045/053 (Single) | Frame size 045/053 (Tandem) | Frame size 060-280 (Single) |

|

|

|

| Dimensions (mm) | |||||

| Size | L | B1 | B2 | H1 | H2 |

| 045/053 Single | 238.2 | 103 | 129.7 | 173.3 | 88.5 |

| 045/053 Tandem | 405 | 103 | 129.7 | 173.3 | 87 |

| 060/068 | 255.9 | 1 06.0 | 135.5 | 173.9 | 99.4 |

| 069/078 | 278.3 | 1 08.9 | 138.2 | 178.9 | 95 |

| 089/100 | 295.3 | 112.4 | 139.2 | 187.3 | 99 |

| 115/130 | 316.9 | 121.9 | 148.1 | 204.3 | 110 |

| 147/165 | 333.3 | 131.9 | 152.6 | 208.3 | 112 |

| 210/250/280 | 418.9 | 155 | 172.2 | 245 | 136 |

Download

Danfoss H1P Closed Circuit Axial Piston Pumps Service Manual |

|

|

|

Danfoss H1P Closed Circuit Axial Piston Pumps Parts List |

FAQS

- What is the maximum operating pressure for the Danfoss H1P69?

The Danfoss H1P69 Closed-Circuit Piston Pumps have a maximum operating pressure of up to 250 bar. The pumps are built with high-strength materials and components that ensure they can handle extreme pressure while still delivering efficient performance.

- How does the Danfoss H1P69 pump compare to other similar products on the market?

The Danfoss H1P69 pump is a reliable, high-performance closed-circuit piston pump that offers superior efficiency and durability compared to other similar products on the market. It features an axial displacement design and adjustable pressure control to ensure consistent pressure levels. Additionally, its advanced self-lubricating materials guarantee long life and reliability in all operating conditions. All these features make the Danfoss H1P69 pump an ideal choice for engineers looking for reliable performance in critical applications.

- How long will the Danfoss H1P69 last?

The Danfoss H1P69 Closed-Circuit Piston Pumps are designed for a long life and durable performance. They are constructed with high-grade materials for superior strength, with an innovative bearing and seal system that ensures maximum uptime and minimum repair costs. With proper maintenance, the Danfoss H1P69 can last for up to five years or more.

- What are the benefits of using Danfoss H1P69 Closed-Circuit Piston Pumps?

The Danfoss H1P69 Closed-Circuit Piston Pumps offer high efficiency and low noise operation, reducing the cost of ownership. The pumps are designed for continuous duty cycle, with a maximum pressure of 420 bar and provide a smooth output flow regardless of the load. The design also minimizes pump vibration and enables efficient cooling, resulting in greater overall pump performance and reliability.

Related products

-

H1P Closed Circuit Axial Piston Pumps

Danfoss H1P250 Closed-Circuit Piston Pumps

Rated 0 out of 5Read more -

H1P Closed Circuit Axial Piston Pumps

Danfoss H1P147 Closed-Circuit Piston Pumps

Rated 0 out of 5Read more -

H1P Closed Circuit Axial Piston Pumps

Danfoss H1P89 Closed-Circuit Piston Pumps

Rated 0 out of 5Read more -

H1P Closed Circuit Axial Piston Pumps

Danfoss H1P60 Closed-Circuit Piston Pumps

Rated 0 out of 5Read more -

H1P Closed Circuit Axial Piston Pumps

Danfoss H1P53 Closed-Circuit Piston Pumps

Rated 0 out of 5Read more